A wide range of engineering services

Here at McNeil Engineering, we provide comprehensive design services that include civil engineering, structural engineering, land surveying, high-definition scanning (HDS), landscape architecture and consulting services to the private and public sectors. We also offer consulting services for cities, urban designers, urban planners, and others in the Utah construction market. With so much on offer, we figured now would be a good time to go into greater detail regarding our services and what they entail.

Here at McNeil Engineering, we provide comprehensive design services that include civil engineering, structural engineering, land surveying, high-definition scanning (HDS), landscape architecture and consulting services to the private and public sectors. We also offer consulting services for cities, urban designers, urban planners, and others in the Utah construction market. With so much on offer, we figured now would be a good time to go into greater detail regarding our services and what they entail.

Civil Engineering in Utah and other states

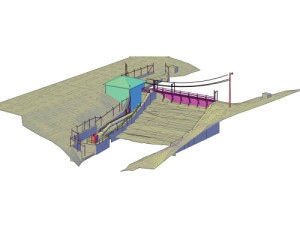

Let’s start with the core of what we do. We are civil engineers first and foremost. But what exactly is it that civil engineers do? Well, in short, civil engineers work closely with others in the construction industry, from architects to contractors, to ensure construction projects progress as they should. Many of their tasks include site surveying ground condition tests, inventory, and materials and equipment maintenance and support. Civil engineers are also responsible for coming up with solutions that take the weather and other geologic factors into account.

Structural Engineering for Long-Lasting Projects

Structural engineering of the type we do fits specifically into the wheelhouse of civil engineering. Structural engineering in this context focuses mainly on the framework of a structure. Engineers design the structures to ensure they can withstand whatever stresses or pressures they may encounter in their environment. The key for structural engineers on projects like ours is to ensure that the buildings and structures we work on remain safe, reliable, and secure at all times.

Land Surveying Where You Need It

Another big part of what we do is land surveying. It’s a critical part of any construction project. There are different types of land surveying, but civil engineers utilize this technique in specific ways. Surveying in civil engineering represents the collection and analysis of specific data regarding the land under survey. Specific measurements of the horizontal and vertical lengths between points will also be recorded. Details will be documented regarding specific aspects of the land, such as size, shape, formation, and soil. Quality and accurate land surveys can set the foundation for a successful project.

Landscape Architecture for Beautiful Grounds

Another important aspect of what we do includes landscape architecture. Put simply, landscape architecture is described as designing specific outdoor spaces that integrate well within an overall project. In our case, we design large landscape architecture projects, such as those for green spaces, a town square, municipal playground, and so much more. Keep in mind there are significant differences between landscape architecture and landscape design. Landscape architects have a degree and they generally work on larger public works projects, whereas a landscape designer often works on residential and smaller-scale projects. Landscape architects are experts in their field.

Consultation Services for Companies Who Need an Expert

We also provide a wide range of consulting services to companies that require a committed and knowledgeable professional to help them with their engineering needs. These are often companies that do not have the in-house expertise they need to get the job done successfully. Our consulting civil engineers advise our clients on the design, development, and construction of projects of all shapes and sizes. We pride ourselves on offering consulting services that ensure safe, efficient, and fully resourced project completion. When you need a consultant you can count on McNeil Engineering.

Other Services We Offer

Now that you’ve learned more about the human aspect of our resources, take a few minutes to learn about some of the other services we offer. We provide a wide range of engineering, surveying, and consulting services. But these services would not be nearly as effective were not for our technologies. We use the latest technologies suitable for engineering projects.

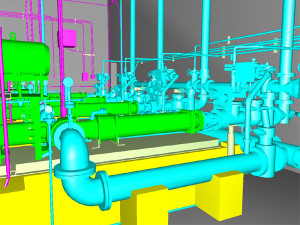

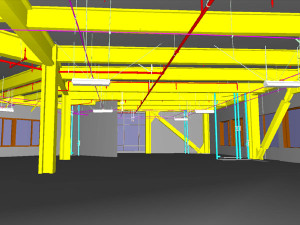

One such example is laser scanning. 3D laser scanning has become an industry norm. Advancements in hardware, software, and workflows have made laser scanning a viable option for projects of all sizes. Laser scanning allows our surveyors to collect tremendous amounts of precise data at high speeds. We use the most advanced, high-definition laser scanners, total stations, and modeling and point cloud software to provide comprehensive, record surveys, 3D CAD models and detailed 2D isometric drawings.

We also have extensive expertise in BIM 3D modeling. Building Information Modeling (BIM) is essentially a technological solution that allows engineers to view a digital representation of a building as well as specific characteristics of its functionality. BIM is a model-based process that provides insight to help you plan, design, construct, and manage buildings and infrastructure.

And guess what? That’s not all. If you need consulting services for roofing, paving, and even construction administration, we have the people and experience you need to ensure the job gets done right the first time, every time. We invite you to take a moment to peruse the various projects we have completed in Utah and around the country. Let’s work together!

3D printing is a relatively new and exciting technology. Finding applications in fields ranging from manufacturing to medicine; 3D printing allows you to produce functional components using additive manufacturing. 3D printing is here to stay because it reduces material wastage, saves time, and improves overall efficiency.

3D printing is a relatively new and exciting technology. Finding applications in fields ranging from manufacturing to medicine; 3D printing allows you to produce functional components using additive manufacturing. 3D printing is here to stay because it reduces material wastage, saves time, and improves overall efficiency. There have been interesting and mind-blowing innovations in the science world over the years, but few might have the “hurricane” impact as 3D printing when it becomes the main scale. The internet rush of the late 20th century and the early 21st century resulted in many of the fascinating things we now enjoy including Blockchain tech, Data Analytics, Virtual meetings, and co. And yet many believe 3D printing will be bigger, especially for Civil Engineering; how inspiring!

There have been interesting and mind-blowing innovations in the science world over the years, but few might have the “hurricane” impact as 3D printing when it becomes the main scale. The internet rush of the late 20th century and the early 21st century resulted in many of the fascinating things we now enjoy including Blockchain tech, Data Analytics, Virtual meetings, and co. And yet many believe 3D printing will be bigger, especially for Civil Engineering; how inspiring!

Since its inception in the 1980s, 3D printing (additive manufacturing) has come a long way. 3D printing was originally envisioned as a tool for rapid prototyping in the manufacturing industry. But in the last decade, it has evolved to cover lots of new and exciting technologies.

Since its inception in the 1980s, 3D printing (additive manufacturing) has come a long way. 3D printing was originally envisioned as a tool for rapid prototyping in the manufacturing industry. But in the last decade, it has evolved to cover lots of new and exciting technologies.